Fasteners and Machining: Improving the Production Refine

Fasteners and Machining: Improving the Production Refine

Blog Article

Browsing the World of Fasteners and Machining: Techniques for Precision and Rate

In the complex realm of bolts and machining, the quest for accuracy and speed is a perpetual challenge that requires meticulous attention to information and tactical preparation. From comprehending the diverse selection of fastener kinds to selecting ideal products that can withstand extensive demands, each step in the procedure plays a critical function in achieving the desired outcome. Accuracy machining techniques additionally raise the intricacy of this craft, requiring a fragile balance in between technical experience and cutting-edge methods. As we delve right into the methods that can boost both speed and performance in this domain, the interaction between quality assurance procedures and operational excellence emerges as a crucial focal point.

Understanding Fastener Kind

When picking fasteners for a job, understanding the different types readily available is essential for guaranteeing ideal efficiency and dependability. Screws are utilized with nuts to hold materials together, while screws are functional bolts that can be made use of with or without a nut, depending on the application. Washers are vital for dispersing the lots of the fastener and avoiding damages to the product being attached.

Picking the Right Materials

Understanding the significance of selecting the right products is extremely important in ensuring the optimal performance and dependability of the selected bolt types reviewed formerly. When it involves bolts and machining applications, the product selection plays a crucial duty in establishing the general strength, sturdiness, corrosion resistance, and compatibility with the designated environment. Different materials offer varying residential properties that can substantially affect the performance of the fasteners.

Typical products used for fasteners include steel, stainless steel, titanium, brass, and aluminum, each having its distinct strengths and weak points. Steel is renowned for its high toughness and toughness, making it ideal for a large range of applications. Stainless steel uses excellent corrosion resistance, perfect for settings susceptible to moisture and chemicals. Light weight aluminum is corrosion-resistant and light-weight, making it suitable for applications where weight reduction is vital. Brass is usually selected for its visual allure and outstanding conductivity. Titanium is known for its exceptional strength-to-weight proportion, making it optimal for high-performance applications. Selecting the ideal product involves thinking about variables such as toughness needs, environmental conditions, and budget plan constraints to guarantee the desired performance and longevity of the fasteners.

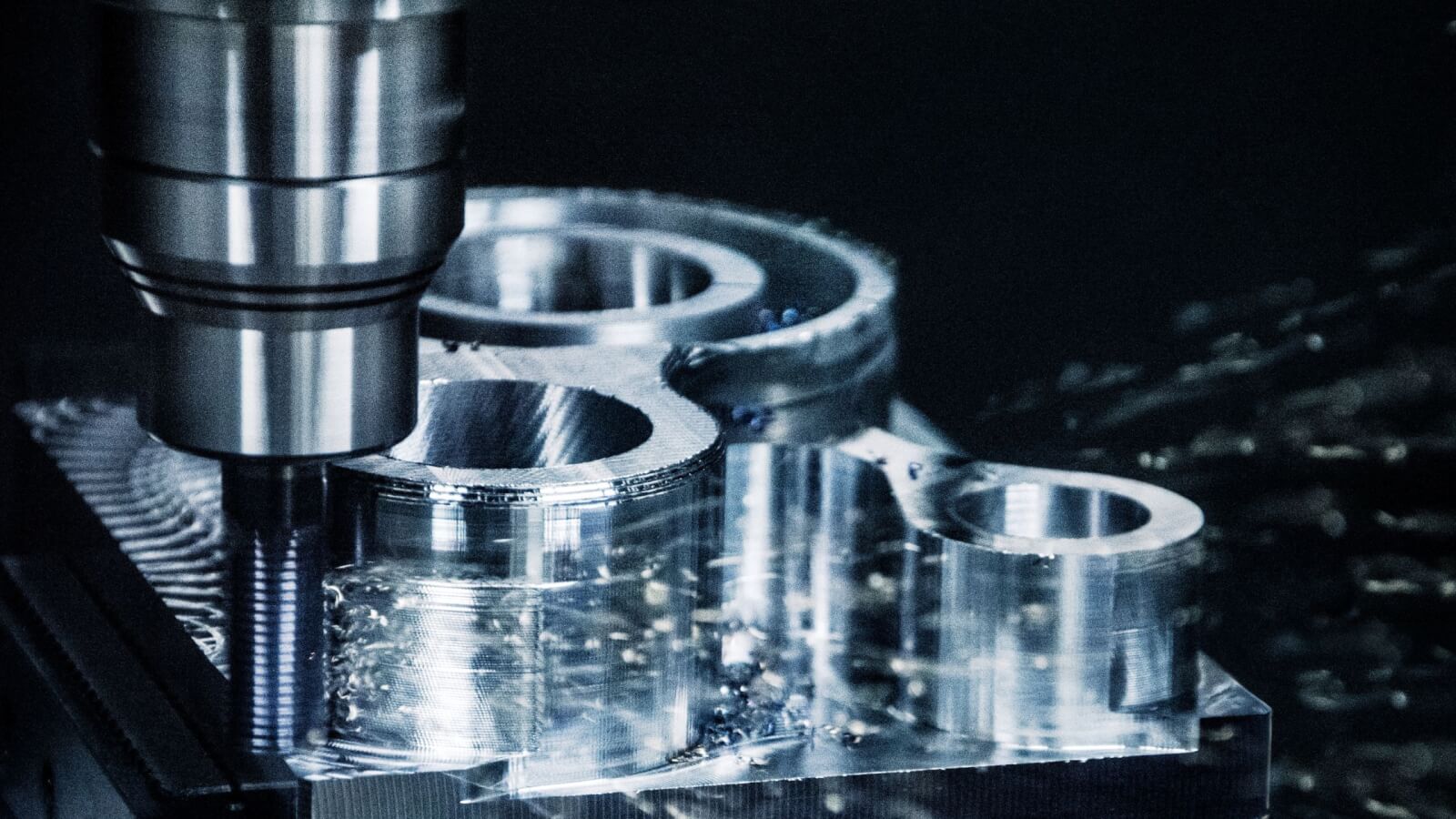

Accuracy Machining Techniques

Along with CNC machining, other precision strategies like grinding, turning, milling, and boring play crucial duties in bolt production. Grinding assists accomplish great surface area coatings and tight dimensional tolerances, while turning is usually used to create cylindrical elements with exact sizes. Milling and exploration procedures are necessary for shaping click to find out more and producing openings in fasteners, guaranteeing they meet exact specs and feature properly.

Enhancing Rate and Effectiveness

To enhance fastener production processes, it is necessary to streamline operations and implement reliable strategies that enhance precision machining methods. One key strategy for boosting rate and efficiency is the implementation of lean production principles. By decreasing waste and focusing on constant renovation, lean techniques assist optimize and remove bottlenecks operations. In addition, purchasing automation innovations can dramatically increase production speed. Automated systems can manage repeated jobs with precision and rate, permitting workers to focus on even more complicated and value-added activities. Embracing Just-In-Time (JIT) supply administration can additionally boost performance by making sure that the best products are readily available at the correct time, decreasing excess inventory and minimizing preparations. Fostering a society of collaboration and interaction amongst team participants can improve general performance by advertising transparency, analytical, and technology. By combining these strategies, suppliers can achieve an equilibrium between rate and precision, eventually boosting their affordable side in the bolt sector.

Quality Assurance Steps

Carrying out rigorous quality control procedures is crucial in guaranteeing the integrity and consistency of bolt products in the manufacturing process. Fasteners and Machining. Quality control measures encompass various phases, beginning from the option of raw materials to the last inspection of the completed fasteners. This entails assessing variables such as material composition, durability, and stamina to assure that the bolts satisfy industry criteria.

Regular calibration of tools and machinery is vital to preserve uniformity in manufacturing and make certain that fasteners fulfill the necessary tolerances. Executing stringent methods for recognizing and attending to non-conformities or defects is important in preventing substandard products from getting in the market. By establishing a detailed quality assurance framework, producers can maintain the track record of their brand and provide bolts that fulfill the greatest standards of efficiency and sturdiness.

Conclusion

In the elaborate realm of fasteners and machining, the pursuit for accuracy and rate is a perpetual challenge that demands meticulous focus to detail and critical preparation. When it comes to fasteners and machining applications, the product choice plays a crucial function in determining the total toughness, durability, deterioration resistance, and compatibility with the designated setting. Accuracy machining entails numerous innovative techniques that make certain the limited resistances and requirements needed for fasteners.In enhancement to CNC machining, various other precision strategies like grinding, transforming, milling, and drilling play important roles in visit this web-site fastener manufacturing.To enhance bolt manufacturing procedures, it is crucial to streamline operations and carry out efficient techniques that complement accuracy machining techniques.

Report this page